التصنيفات

مدونة جديدة

اللحام بقعة معدنية بالموجات فوق الصوتية

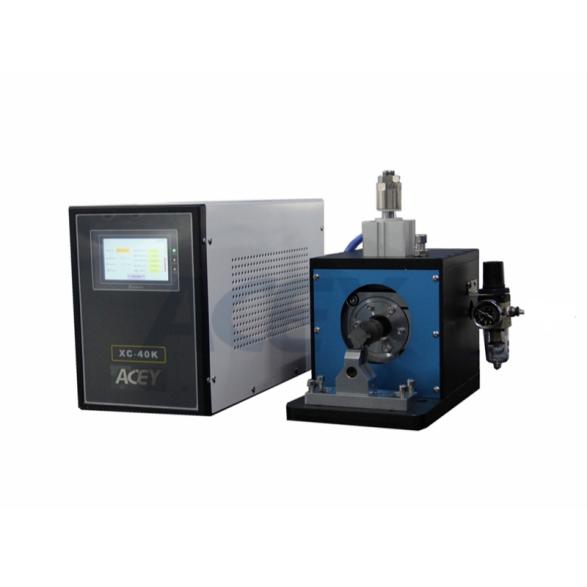

June 11 , 2021ultrasonic metal spot welder: it is similar to friction welding, but there are difference, ultrasonic welding takes a short time and the temperature is lower than recrystallization;

it is also different from pressure welding because the static pressure applied is much less than pressure welding.

it is generally believed that in the initial stage of the ultrasonic welding process, the tangential vibration removes the oxides on the metal surface, and the protruding part of the rough surface produces repeated micro-welding and destruction, which increases the contact area and increases the temperature of the welding zone. High, plastic deformation occurs at the interface of the weldment. in this way, under the action of contact pressure, when they approach each other to the distance at which atomic gravity can act, a solder joint is formed. The welding time is too long, or the ultrasonic amplitude is too large, which will reduce the welding strength or even destroy it. ultrasonic metal welding machine is an advanced high-tech equipment that converts high-frequency electric energy into mechanical vibration energy through a transducer and acts on the workpiece, generating high-frequency friction between the surfaces of the two workpieces, until the surfaces of the two workpieces are heated and welded together. it can perform spot and strip welding on thin materials of conductive metals such as copper, silver, chromium-nickel, etc. it can be widely used in thyristor chip leads, fast fuse melt holders, electrical lead terminals, lithium ion, and nickel point and strip welding of electrode pieces and tabs of lithium battery

working principle and characteristics

ultrasonic metal welding machine is a new type of equipment which converts the energy of ultrasonic vibration into friction energy and transmits it to the metal surface to be welded by using the principle of ultrasonic high-frequency vibration and friction, and makes the metal structure molecules fully activated to form the fusion between molecular layers under the condition of applying pressure to the metal surface while producing heat from friction.

functional features:

microcomputer control, electronic tuning frequency,LCD display, continuous adjustable power, simple operation, stable and reliable work; strong welding, good consistency, welding parts with solid welding surface, high strength, beautiful, environmental protection and other characteristics. easy to operate, built-in electronic protection circuit, safe to use, used for the same kind of metal welding, can implement single or multi-point welding of non-ferrous metal; widely used in battery and hardware products industry.

ACEY supports to cusmomize different size welder head according to client requirement.