What is the future of the lithium battery market?

Lithium-ion batteries (LIBs) are now ubiquitous in daily life, in increasingly diverse applications including electric cars, power tools, medical devices, smart watches, drones, satellites, and utility-scale storage etc. In the future, as people's demand for clean energy continues to increase, lithium-ion batteries will be more widely used in new energy fields such as solar and wind power. In addition, with the advancement of technology and the continuous improvement of lithium-ion battery technology, the energy density, safety, cycle life, cost and other aspects of lithium-ion batteries will be improved. Future lithium-ion batteries will be lighter, smaller, more portable, efficient, and their application range will be even wider. They are one of the main development directions in the field of energy storage and conversion in the future.

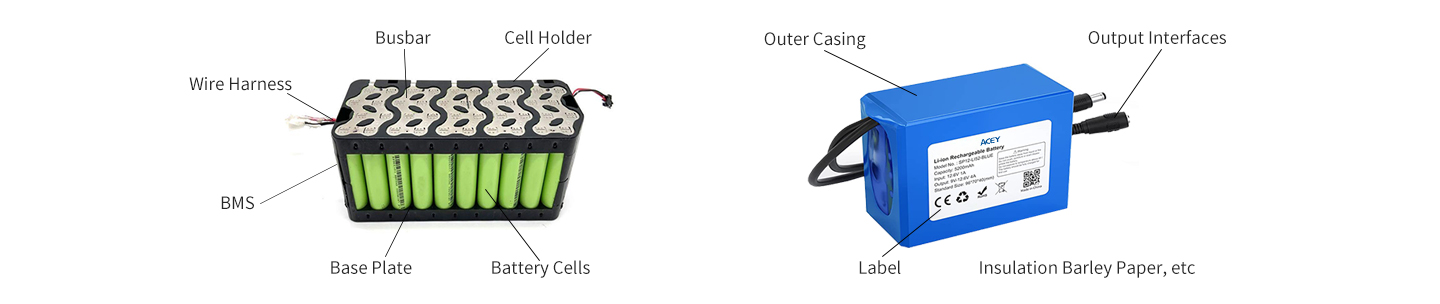

What are the components of a lithium battery pack?

The main materials of the lithium battery pack include batteries, BMS, casing, barley paper, EVA, brackets, high-temperature tape, nickel sheets, wires, output interfaces, labels, safety tubes, etc.

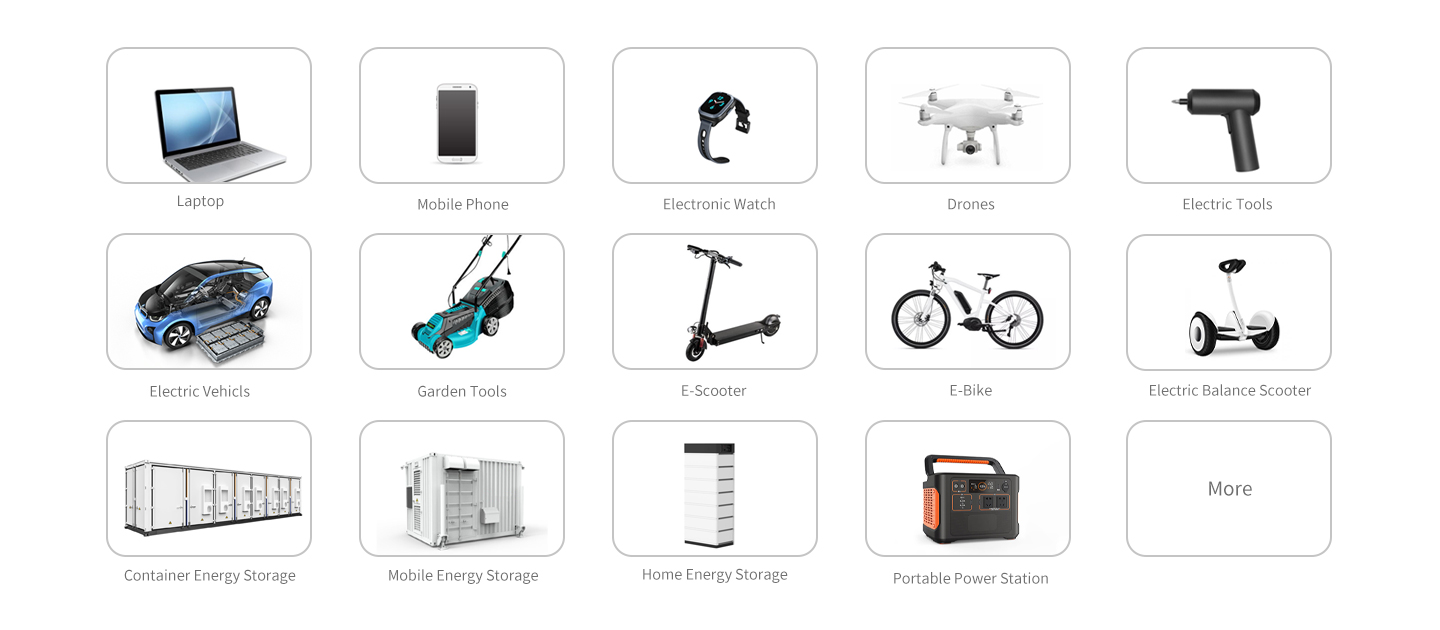

What are the applications of lithium battery packs?

Lithium battery packs are widely used in various applications due to their high energy density, low self-discharge rate, and long cycle life. Here are some common applications of lithium battery packs:

Portable Electronics: Lithium battery packs are commonly used in portable electronic devices such as smartphones, tablets, laptops, and digital cameras.

Electric Vehicles: Lithium battery packs are used in electric vehicles such as cars, bikes, and scooters. They provide high power and energy density, making them ideal for use in electric vehicles.

Energy Storage: Lithium battery packs are used for energy storage in renewable energy systems, such as solar and wind power. They can store excess energy generated during peak hours for use during off-peak hours.

Medical Devices: Lithium battery packs are commonly used in medical devices such as pacemakers, defibrillators, and insulin pumps. They provide reliable and long-lasting power to these critical devices.

Aerospace and Defense: Lithium battery packs are used in aerospace and defense applications due to their high energy density and reliability. They are used in aircraft, satellites, and other military applications.

Robotics: Lithium battery packs are commonly used in robotics applications such as drones, unmanned ground vehicles, and humanoid robots.

Etc

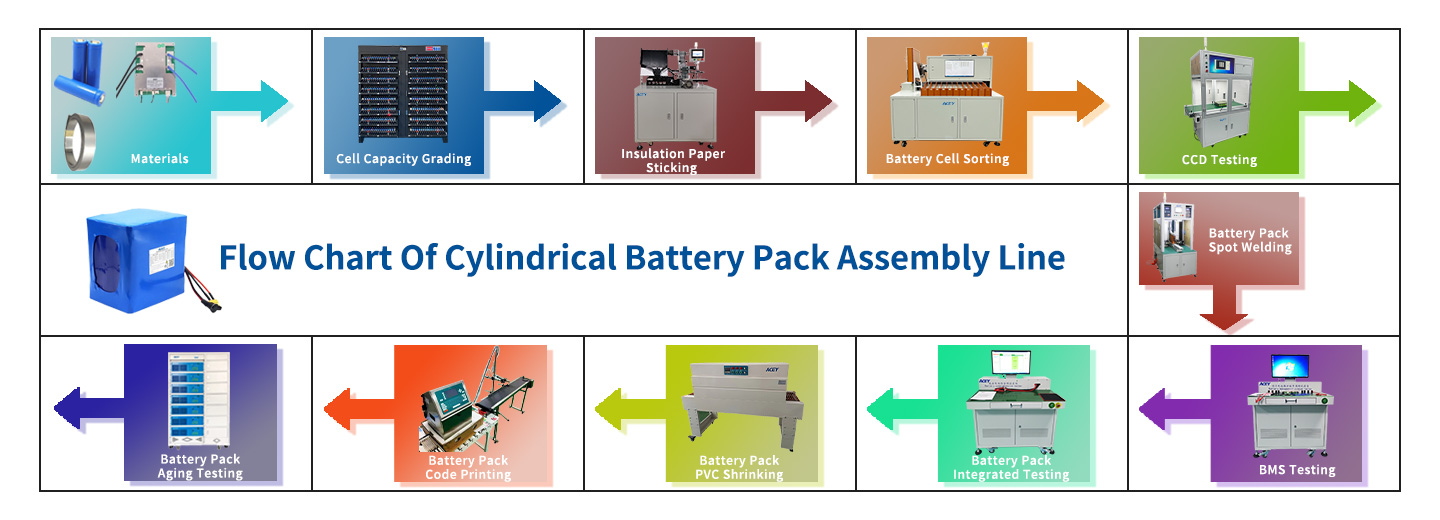

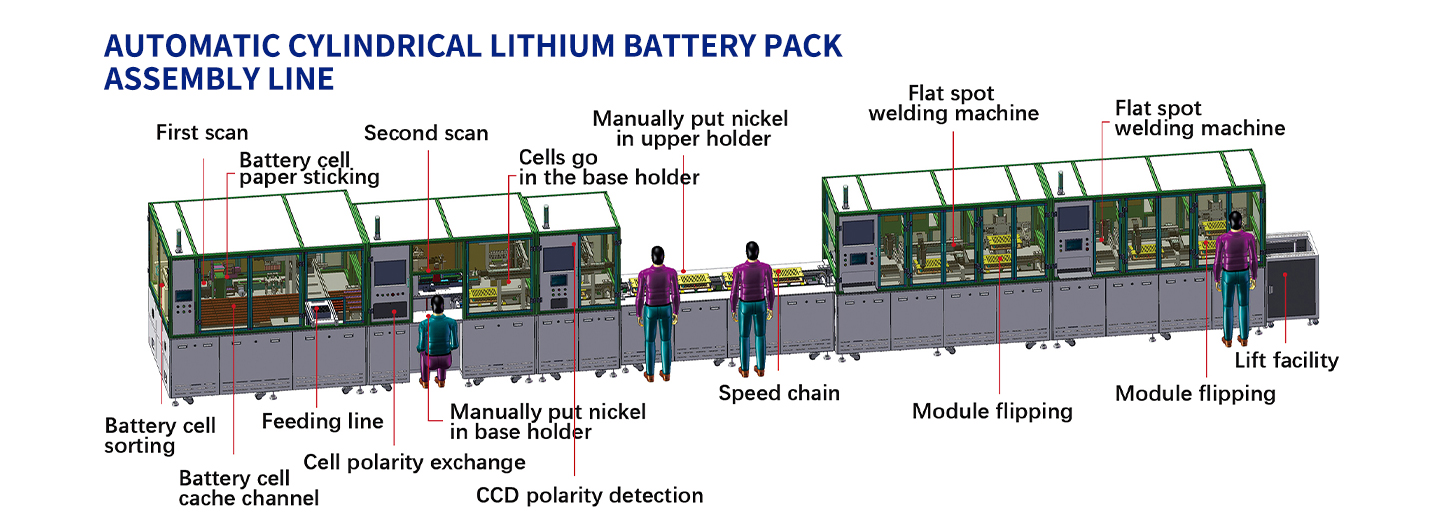

What equipments do you need to assemble a lithium battery pack?

The main equipments of cylindrical battery pack assembly line include battery formation and grading system, battery insulation paper sticking machine, battery sorter, CCD tester, battery pack spot welder, bms tester, comprehensive tester, heat shrink wrap machine, inkjet batch coding machine, battery pack tester.

Option 1- Semi-automatic cylindrical battery pack assembly line

Option 2- Full-automatic cylindrical battery pack assembly line

What is the assembly process of lithium battery packs?

Step 1-Battery Cell Capacity Grading

1) Product Description

Battery cell capacity grading machine is used to test capacity, charging and discharging of single battery, to achieve the consistency of battery cells.

2) Working Principle and Features

The capacity sorting of Li-ion battery is screened by the cell capacity grading cabinet, the function of the cell capacity grading cabinet is similar to the charger, except that it can charge and discharge a large number of batteries at the same time.

Lithium batteries are managed by computer to get the data of each testing point, so as to analyze the size of these batteries' capacity and internal resistance and other data to determine the quality level of the batteries, and this process is capacity sorting.

*Each channel can be started and stopped at a single point, and the response speed is fast

*The operation is simple, convenient and intuitive

*Modular design, easy to maintain

*The digital current and voltage automatic calibration function

*Using network connection and SQL database

*The hardware technology is advanced, stable and durable

3) Product Model

|

Type |

Normal or energy-saving type(can save energy up to 40% ) |

Energy-saving type |

Customized |

||||

|

Cylindrical Battery |

18650/21700/26650/32650/32700 |

32140/33140/34189 |

|||||

|

Voltage and Current |

5V/1A |

5V/2A |

5V/3A |

5V/6A |

5V/10A |

5V/20A |

|

|

Channels |

256/512 |

128/256 |

|||||

|

Products |

|||||||

Step 2-Battery Cell Insulation Paper Pasting

1) Product Description

The function of Insulation Paper Pasting Machine is to paste a layer of barley paper outside the positive pole of the cylindrical battery, so that it has good insulation, wear resistance, waterproof and other characteristics, and effectively prevent the positive and negative short circuit of the power battery pack during vibration.

2) Working Principle and Features

The battery sticker machine is controlled by a PLC stepper motor and cylinder to complete the positive electrode pasting of the finished battery cell with barley paper.

Using a cylinder driven cutting knife for stamping, four battery cells are punched and attached at once. The slices are made of high-speed steel material, with high wear resistance, good product quality, and high production efficiency.

It can be used for multiple purposes, and if different cell models need to be pasted with barley paper, simply change the mold and you can switch between them.

*Approximately 4000 cylindrical batteries can be completed per hour.

*High consistency of placement and low defect rate.

*Fault information reminder function, fault sound and light alarm, can quickly diagnose faults.

3) Product Model

| Mould | Replaceable | Replaceable | Customized |

| Cylindrical Battery | 18650/21700/26650/32650/32700 | 32140/33140 | |

| Products |

|

|

More |

Step 3-Battery Cell Sorting

1) Product Description

The lithium-ion battery sorter is used to sort the internal resistance and voltage of cylindrical lithium batteries. The built-in tester adopts HIOKI3561/HK3561 high-precision internal resistance and voltage testing system, and the test results are analyzed by computer to generate classification data, and the historical test data can be queried, counted and exported. It is also equipped with barcode scanning function, which can analyze and save the battery test data. It adopts precise servo motor control and synchronous belt drive, which greatly improves the testing speed and stability of test data.

2) Working Principle and Features

The battery is manually loaded into the lower slot, then the battery is tested for internal resistance and voltage, the tested battery flows into the belt slot, the QR code or barcode on the battery is automatically scanned, the data is automatically entered into the system, and finally the battery is pushed into the corresponding slot.

3) Product Model

| Cylindrical Battery | 18650/21700/26650/32650/32700 | 32140/33140 | Customized | ||

| Mould | Replaceable | ||||

| Barcode Scanner | Optional | ||||

| Tester | HK3561/HIOKI3561 | ||||

| Channels | 5 | 6 | 11 | 5 | |

| Product |

|

|

|

|

More |

Step 4-Battery Positive And Negative Polarity Detection

1) Product Description

CCD tester is a device for testing whether the battery polarity is correctly placed in the automatic spot welder fixture. It is used in conjunction with automatic spot welding machine to avoid major accidents caused by short circuit of batteries due to manual placement errors.

2) Working Principle and Features

Through the CCD computer system, set the measurement mode and accuracy parameter range, adjust the parameters, and the equipment starts to monitor and enter the working state.

Action process: manual loading of the whole box of batteries → start CCD detection button →CCD system analysis → CCD system discrimination (OK/NG) → material receiving personnel to receive materials.

Features:

3) Product Model

| Cylindrical Battery | 18650/21700/26650/32650/32700/32140/33140 etc | Customized | |

| Camera | HIKVISION 6-12 Million Pixels | ||

| Conveyer Belt | Without | With | |

| Product |

|

|

More |

Step 5-Battery Pack Spot Welding

1) Product Description

Battery pack spot welder is used to weld nickel sheets with many lithium batteries into a group pack, which is suitable for battery pack assembly in the factory for 14500 18650 21700 26650 32700 etc multi-parallel multi-series combination. It can be used in electric tool battery, torsion car battery, Energy Storage Battery Pack, Scooter Electric Vehicle Battery, etc.

2) Working Principle and Features

Battery spot welder, also known as resistance welder, is the principle of welding by using the resistance heat generated by the electric current through the welding joint of the workpiece.

When working, two electrodes squeeze the workpiece, so that the two layers of metal form a certain contact resistance under the pressure of the two electrodes. When the welding current flows from one electrode to the other, a transient thermal weld is formed at the two contact resistance points, and the welding current flows instantaneously along the two workpieces from the other electrode, forming a circuit without destroying the internal structure of the workpiece to be welded.

3) Product Model

| Cylindrical Battery | 18650/21700/26650/32650/32700/32140/33140 | Customized | ||||

| Current | 5000A/8000A/10000A | |||||

| Welding Power | DC Inverter/Transistor | |||||

| Welding Method | Manual | Automatic | ||||

| Product Type | Gantry | With slide rail | Single side | Double side | With PC | |

| Product |

|

|

|

|

|

More |

Step 6-Battery Management System Testing

1) Product Description

BMS tester is used in the safety test of lithium battery protection board, to detect whether the functional indicators of the protection board are within the reasonable parameters.

2) Working Principle and Features

BMS tester uses capacitance to simulate battery charge and discharge, and conducts overcharge test, overcharge recovery test, overdischarge test, overdischarge protection recovery test, standby power consumption test, overcurrent test, etc. for the protection board.

Features:

3) Product Model

| Series | 16/20/24/32 | Customized | |

| Current | 120/150/200/300/400/500/600/800A etc | ||

| PC | With | Without | |

| Product |

|

|

More |

Step 7-Battery Comprehensive Testing

1) Product Description

The battery comprehensive tester is a device for fast and accurate testing of finished battery performance. The main test items include: open circuit voltage, AC internal resistance, discharge test, discharge over current test, short circuit protection test, charge test and charge protection test.

2) Working Principle and Features

The battery comprehensive tester is to apply a load to the battery or apply a small AC current to measure the open circuit voltage, AC internal resistance, discharge test, discharge overcurrent test, short circuit protection test, charge test and charge protection test and other parameters to quickly screen and judge the performance of the battery and good or bad, by setting the upper and lower limits of the measurement parameters, it is easy to quickly detect the bad battery from a batch of finished batteries.

3) Product Model

| Voltage | 50/60/100/120V etc | Customized | |

| Current | 120/200/300/500/600A etc | ||

| Product |

|

|

More |

Step 8-Battery Pack PVC Shrinking

1) Product Description

Heat shrink wrap machine is designed for cylindrical and combined battery heat shrink packaging process, using a combination of far-infrared and circulating wind heating technology to ensure uniform heat shrinkage of the battery plastic cover, beautiful deformation and high concentration. Suitable for PVC, PP, PE, POF and other types of shrink film.

2) Working Principle and Features

Heat shrinking machine uses heat shrink films to change the irregular arrangement between the original molecules under heating. Under infrared and other thermal radiation, plastic molecules rearrange tightly, greatly reducing the original area and adhering to the surface of the product to achieve packaging purposes.

3) Product Model

| Model | 4020C | 4525C | 5035C | Customized |

| Shrink film | POF PVC PP | POF PVC PP PE | ||

| Tunnel size(mm) | 1200x400x200 | 1200 x 450 x 250 | 1200 x 500 x 350 | |

| Shrinkable product size(mm) | 350*150 | 400*200 | 450*300 | |

| Product |

|

|

|

More |

Step 9-Battery Pack Code Printing

1) Product Description

Inkjet batch code printing machine is sprayed on the outer surface of the battery with the information of the battery, including the manufacturer, model, Production date, voltage, capacity, Energy, production batch number, etc.

2) Working Principle and Features

The working principle of continue inkjet printer is that ink is continuously ejected from a single nozzle through pressure, and after crystal oscillation, it breaks and forms ink dots; After being charged with ink dots and deflected under high voltage, the moving object surface is scanned into characters.

The products are widely used in the food industry, cosmetics industry, pharmaceutical industry, automotive and other parts processing industries, wire and cable industry, aluminum plastic pipe industry, tobacco and alcohol industry, and other fields. Can be used for printing English, Simplified Chinese, Arabic numerals, serial numbers, barcodes, time, date, trademark patterns, special fonts, and other content.

3) Product Model

| Product Type | Drop on Demand(Handheld) | Drop on Demand(with conveyor belt) | Continue ink jet printer | |

| Product |

|

|

|

More |

Step 10-Battery Pack Aging Testing

1) Product Description

The battery pack life cycle tester is a charge/discharge cycle aging test for battery packs with analog motor to calculate the capacity and the number of charge/discharge or working life of the battery pack. The test items include: battery charge protection voltage, discharge protection voltage, capacity, etc.

2) Working Principle and Features

Battery pack life cycle tester system mainly includes PC software, USB hub, router, aging instrument. The core lies in the aging instrument, the main control chip of the aging instrument is 32-bit ARM chip, which is much faster than the traditional microcontroller in execution and has higher accuracy in measuring voltage and current. The device has four test steps: charging, discharging, shelving, and cycling. By editing the corresponding steps, the battery can be tested in accordance with the set process.

3) Product Model